Automotive and Manufacturing Data Solutions

|

|

Unlocking Data-Driven Efficiency for Industrial Manufacturing Operations

Software Toolbox delivers scalable software solutions, world-class service and expert support to help the Automotive and Manufacturing, industries eliminate data silos, improve productivity, and accelerate digital transformation. Our configurable, off-the-shelf software enables secure, real-time data exchange and precise operational data collection to optimize production, automation, and efficiency. Designed for industry-specific needs, our solutions consolidate data from diverse sources, including robotic assembly lines, CNC machines, PLCs, drives, motion control, industrial sensors, material handling systems, predictive maintenance platforms, factory control rooms, enterprise resource planning (ERP) systems, and cloud applications—into a unified, scalable data collection system. Whether improving production line efficiency, ensuring quality control, or optimizing machine performance, our solutions help provide the connectivity and insights needed to drive smarter, faster decisions.

Find out which Automotive & Manufacturing companies put their trust into solutions by Software Toolbox »

Intelligent Solutions for Automotive and Manufacturing Excellence

-

Enhancing Production Processes

-

Optimizing Assembly Line Management

-

Preventing Downtime with Predictive Maintenance

-

Improving Supply Chain Visibility

-

Driving Sustainability with Environmental Monitoring

Enhancing Production Processes

Automotive and machinery operations depend on real-time insights to optimize resource utilization and output. Software Toolbox’s solutions enable seamless data collection from field devices and control systems, providing operators with instant visibility into production processes. With improved monitoring of key performance indicators, teams can make faster, more informed decisions to maximize productivity.

Optimizing Assembly Line Management

Achieving high efficiency and quality in assembly line processes requires precise control over operating parameters. Software Toolbox’s solutions integrate data from sensors, control systems, and enterprise applications, enabling continuous monitoring and optimization of assembly processes. This ensures reduced waste and increased profitability.

Preventing Downtime with Predictive Maintenance

Equipment failures can lead to costly downtime and lost productivity. Software Toolbox’s solutions facilitate predictive maintenance by collecting, storing, and propagating data used by predictive maintenance software to analyze real-time and historical performance information to detect early signs of equipment issues. By proactively scheduling maintenance based on actual operating conditions, companies can reduce unexpected failures and extend equipment lifespan.

Improving Supply Chain Visibility

Managing inventory, logistics, and procurement is critical in manufacturing environments. Software Toolbox’s solutions help connect operational and business systems, enabling real-time tracking of inventory levels, shipments, and procurement workflows. This allows companies to optimize supply chain management, prevent shortages, and reduce costs through data-driven decision-making.

Driving Sustainability with Environmental Monitoring

Sustainable manufacturing practices require continual tracking of environmental impact. Software Toolbox’s solutions help integrate environmental monitoring systems with operational data, allowing companies to track emissions, resource usage, and waste management in real time. By improving visibility and control over environmental performance, these solutions help organizations meet sustainability goals and regulatory standards.

The Challenges of Connecting Field Data to the Cloud

-

Data Integration

-

Inefficient Data Visualization

-

Operational Data Connectivity

-

Custom Application Development

Challenges

Applications in Automotive and Manufacturing require effective data integration across various systems. Data silos hinder decision-making and complicated operations, creating a need for flexible infrastructure to optimize processes.

Solution

TOP Server and OmniServer empower Automotive and Manufacturing operations by enabling seamless data integration and improved communication across diverse control systems. Cogent DataHub securely integrates historians, databases, and cloud systems with real-time data exchange across complex networks. OPC Router delivers templatized visual workflows for Industry 4.0 integration.

Challenges

Inefficient data visualization and reporting can cause difficulties in process control and equipment monitoring, necessitating intuitive HMI/SCADA extensions for better decision-making.

Solution

Symbol Factory and Dream Report improve data visualization and reporting in Automotive and Manufacturing applications, providing intuitive HMI/SCADA extensions that enhance decision-making and efficiency in process control and equipment monitoring.

Challenges

Integration issues can hinder effective asset performance management, predictive maintenance, and material flow tracking, impacting decision-making throughout critical processes in production.

Solution

Integration solutions like OPC Router and Cogent DataHub deliver secure data connectivity by facilitating seamless integration and real-time and event-driven data exchange.

Challenges

When custom applications are the only solution, or integrating existing custom applications, it can be a struggle to develop and deploy scalable, secure applications that seamlessly integrate with existing systems, hindering real-time decision-making and operational agility in rapidly changing environments. Lack of domain expertise in standards like OPC only adds to the challenge.

Solution

The OPC Data Client Development Toolkit and OPC Wizard Rapid OPC UA Server Development Toolkit enhance application development by providing tools to rapidly create custom, standards enabled clients and servers without having to be an OPC domain expert.

Software Toolbox Solutions for Automotive, Manufacturing & Machinery

Here are examples of our configurable off-the-shelf software solutions for Automotive, Manufacturing & Machinery.

Our consultants help identify the ideal mix that integrates seamlessly into your operations while optimizing performance and cost.

TOP SERVER

TOP Server is a secure platform integrating production control data in automotive and manufacturing using OPC to connect to any HMI, SCADA, MES, or Historian. It supports 1000s of diverse devices and ensures seamless data flow to support decision-making and operational performance.

OPC CLIENT TOOLKIT

OPC Data Client Development Toolkit enables custom OPC client development, optimizing communication across diverse environments. No OPC expertise needed—its logical function calls simplify implementation while ensuring seamless data exchange and robust insights for troubleshooting.

COGENT DATAHUB

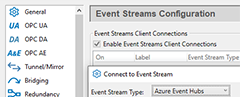

Cogent DataHub securely integrates OT & IT data sources, including OPC, MQTT, Sparkplug, databases, and historians, across complex networks. Enable asset management, optimize production, and achieve large-scale data movement while meeting cybersecurity requirements.

OPC SERVER TOOLKIT

OPC Wizard Rapid OPC Toolkit speeds up secure OPC UA server development, enabling seamless data exchange. Like OPC Data Client, it requires no OPC expertise to add OPC UA to custom applications, serving data to HMI, SCADA, MES, or Historian systems with ease.

OPC ROUTER

OPC Router provides visual workflows for Industry 4.0 at any stage. Supporting OPC, MQTT, databases, ERP, REST/SOAP, and structured data handling, it deploys to edge devices via Docker, Portainer & Kubernetes—helping you drive digital transformation with ease.

SYMBOL FACTORY

Symbol Factory enhances applications with graphics for dashboards and equipment monitoring, allowing operators to make quick decisions, reducing downtime and improving productivity in critical operational areas.

OMNISERVER

OmniServer OPC Server facilitates communication between non-standard serial & Ethernet devices and industrial systems by converting proprietary device protocols into OPC and MQTT but also logging to files and databases, enabling seamless data integration without custom coding.

DREAM REPORT

Dream Report automates reporting for production tracking and asset performance in manufacturing. It offers customizable templates and insights, ensuring stakeholders access critical data for informed decisions.

Uncover Valuable Insights: Browse Blogs, Guides, and Video Tutorials

- Automotive Mirror Manufacturing - PLC to OPC to Excel Integration »

- Paint Shop Air Flow Optimization - ABB PLC to OPC to MySQL Integration at Saab »

- Cogent DataHub V11 Provides Secure Remote Configuration Built In »

- How to Simplify OPC Server Redundancy with Cogent DataHub »

- 4 Ways to Address Security Challenges with DataHub Tunneling »

Video Tutorial

Secure OPC UA Connectivity with Cogent DataHub »

Deployment GuideTOP Server Secure Deployment Guide »

This guide provides best practices that existing and new users should consider if their business needs require deploying TOP Server with maximum security.

Why Work With Software Toolbox? Our Clients Tell Their Story:

"“I would like to express how kind and understanding the consultant was, thank you so much he has saved me from lots of stress. 10 out of 10 for him. Keep shining!”

- Said by a happy customer working for a global tire manufacturer, USA

“I really appreciated the consultant's patience and understanding on the matter. She is a definite asset to the support staff. Her whole demeanor was top notch in my opinion."

- Global automotive supplier, Canada

“The consultant was very knowledgeable on the subject and was able to point me in the right direction to correct my issue very timely.”

- A happy customer working for an automotive supplier, Global

Why Software Toolbox? Data-Focused, Solution-Oriented!

Our world-class support ensures we address your communications and operational challenges with precision and care.

Software Toolbox offers top-tier support and services designed to maximize the value automotive, manufacturing, and machinery companies get from our solutions. Whether optimizing assembly line processes, enhancing production integration, or enabling predictive maintenance, our expert team provides personalized assistance to ensure smooth implementation and quick troubleshooting. With a customer-first approach, 97% of users rate our support as “awesome or excellent.” We empower our clients to overcome operational challenges and optimize performance across applications like asset performance management, environmental monitoring, and data-driven decision-making.

Software Toolbox provides automotive and manufacturing industries with secure, reliable, and scalable data solutions. By seamlessly integrating data across field operations, production facilities, and enterprise systems, we help you overcome communication barriers, drive operational performance, and make smarter, more data-driven decisions in critical areas such as production optimization, sustainability, and supply chain management.

STAY CONNECTED

1-888-665-3678 (US + Canada)

+1-704-849-2773 (Global)

+1-704-849-6388 (Fax)

support.softwaretoolbox.com

WORKING WITH US

WHO WE ARE

RECENT POSTS

Usage subject to our website terms and conditions.