Industrial Connectivity

HMI/SCADA Add-Ins

Digital Transformation

Application Development

Empowering Mining, Metals, and Minerals with ConnectivitySmarter Decisions with Reliable Data and Integration

|

|

Optimizing Connectivity for Heavy Industry Operations

Software Toolbox delivers secure, scalable software solutions that optimize key mining, minerals, and metals applications, including mineral extraction, processing, smelting, refining, reclamation, and environmental remediation. Our industrial connectivity seamlessly integrates legacy and modern systems, enabling real-time data flow across field devices, control systems, HMI/SCADA, command centers, enterprise applications, and the cloud.

By providing secure data collection and seamless integration, our solutions empower real-time decision-making, enhance operational efficiency, support environmental stewardship, and ensure regulatory compliance. With robust, standards-based connectivity, Software Toolbox helps companies maximize efficiency, reduce costs, and achieve long-term success in an increasingly data-driven industry.

Find out which companies in the industry put their trust into solutions by Software Toolbox »

Intelligent Solutions for Mining, Minerals & Metals Excellence

-

Enhancing Mineral Extraction

-

Optimizing Processing & Refinement

-

Preventing Downtime with Predictive Maintenance

-

Ensuring Compliance & Reporting

-

Improving Supply Chain Visibility

-

Driving Sustainability with Environmental Monitoring

Enhancing Mineral Extraction

Mining operations depend on real-time insights to optimize resource utilization and efficiency. Software Toolbox’s solutions enable seamless data collection from field devices and control systems, providing operators with instant visibility into extraction processes. With improved monitoring of key performance indicators, teams can make faster, more informed decisions to maximize productivity.

Optimizing Processing & Refinement

Achieving high recovery rates and product quality in mineral processing requires precise control over processing parameters. Software Toolbox’s solutions integrate data from sensors, control systems, and enterprise applications, enabling applications used for continuous monitoring and optimization of refining processes. This ensures improved efficiency, reduced waste, and greater profitability.

Preventing Downtime with Predictive Maintenance

Mining equipment failures can lead to costly downtime, safety issues, and lost productivity. Software Toolbox’s solutions facilitate predictive maintenance applications with the data needed to analyze real-time and historical performance data to detect early signs of equipment issues. By proactively scheduling maintenance based on actual operating conditions, companies can reduce unexpected failures, extend equipment lifespan, and optimize maintenance costs.

Ensuring Compliance & Reporting & Environmental Stewardship

Strict environmental and safety regulations require continuous monitoring to prevent problems, and timely reporting of compliance status. Software Toolbox’s solutions automate compliance monitoring by collecting and aggregating critical operational data, generating real-time reports on emissions, energy usage, and safety metrics. By improving data accuracy and accessibility, these solutions help companies strengthen regulatory compliance and accountability.

Improving Supply Chain Visibility

Managing inventory, logistics, and procurement is critical in mining operations. Software Toolbox’s solutions connect operational and business systems, enabling real-time tracking of inventory levels, shipments, and procurement workflows. This allows companies to optimize supply chain management, prevent shortages, and reduce costs through data-driven decision-making.

Driving Sustainability with Environmental Monitoring

Sustainable mining practices require continuous tracking of environmental impact. Software Toolbox’s solutions integrate environmental monitoring systems with operational data, allowing companies to track emissions, water quality, and waste management in real time. By improving visibility and control over environmental performance, these solutions help organizations meet sustainability goals and regulatory standards.

The Challenges of Connecting Field Data to the Cloud

-

Data Integration

-

Inefficient Data Visualization

-

Operational Data Connectivity

-

Custom Application Development

Challenges

Applications in MMM require effective data integration across various systems. Data silos hinder decision-making, complicate operations, and impede compliance, creating a need for flexible infrastructure to optimize processes.

Solution

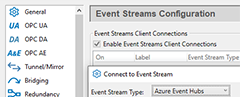

TOP Server and OmniServer empower MMM operations by enabling seamless data integration and improved communication across diverse control systems. Cogent DataHub securely integrates historians, databases, and cloud systems with real-time data exchange across complex networks. OPC Router delivers templatized visual workflows for Industry 4.0 integration.

Challenges

Inefficient data visualization and reporting cause difficulties and compliance issues in process control, equipment monitoring, and environmental compliance within MMM operations, necessitating intuitive HMI/SCADA extensions for better decision-making and efficiency.

Solution

Symbol Factory and Dream Report improve data visualization and reporting in MMM applications, providing intuitive HMI/SCADA extensions that enhance decision-making, efficiency, and compliance in process control and equipment monitoring.

Challenges

Integration issues hinder effective asset performance management, predictive maintenance, material flow tracking, and environmental monitoring, negatively impacting operational efficiency and decision-making throughout critical processes in the production lifecycle.

Solution

Integration solutions like OPC Router and Cogent DataHub deliver secure data connectivity and operational efficiency by facilitating mine-to-mill integration, predictive maintenance, and real-time data exchange, optimizing asset performance and environmental monitoring.

Challenges

When custom applications are the only solution, or integrating existing custom applications, it can be a struggle to develop and deploy scalable, secure applications that seamlessly integrate with existing systems, hindering real-time decision-making and operational agility in rapidly changing environments. Lack of domain expertise in standards like OPC only adds to the challenge.

Solution

The OPC Data Client Development Toolkit and OPC Wizard Rapid OPC UA Server Development Toolkit enhance application development by providing tools to rapidly create custom, standards enabled clients and servers without having to be an OPC domain expert.

Maximize Operational Performance through Data Integration

Here are examples of our configurable off-the-shelf software solutions for Mining, Minerals, and Metals.

Our consultants help identify the ideal mix that integrates seamlessly into your operations while optimizing performance and cost.

TOP SERVER

TOP Server securely integrates field controller data for mining, metals, and minerals, optimizing extraction, processing, and monitoring. With native OPC connections to HMI, SCADA, MES, and Historians, it provides an open, adaptable platform that evolves with your data needs.

OPC CLIENT TOOLKIT

OPC Data Client Development Toolkit is a toolkit for building custom OPC clients that removes the need to be an OPC domain expert, supporting communication and integration across diverse mining, metals, and minerals environments for enhanced operational flexibility.

COGENT DATAHUB

Cogent DataHub delivers secure real-time integration of real-time & historical data from OT and IT systems for asset management, production optimization, and environmental monitoring. It enables data exchange between business systems, cloud platforms, and partners while ensuring cybersecurity.

OPC SERVER TOOLKIT

OPC Wizard Rapid OPC Toolkit a toolset for accelerating OPC UA server development, ideally for custom software applications that need to integrate into your solutions stack, enabling secure, high-performance servers for equipment monitoring and resource management in mining operations.

OPC ROUTER

OPC Router transforms and integrates data from various sources through templatized visual workflows, including OT, ERP and cloud systems for Industry 4.0 evolution, supporting applications like mine-to-mill integration, predictive maintenance, and material tracking in mining operations.

SYMBOL FACTORY

Symbol Factory provides SCADA and HMI applications with a rich library of graphics for mining, metal, and mineral operations. It helps operators visualize plant status and make data-driven decisions, minimizing downtime.

OMNISERVER

OmniServer OPC Server integrates legacy equipment and advanced sensors by supporting non-standard serial & Ethernet protocols. Data is delivered using standard OPC and MQTT connections, or can be logged to databases/files, improving operational visibility and decision-making in mining operations.

DREAM REPORT

Dream Report automates reporting for production tracking, asset performance, and compliance analytics. It provides customizable templates and cloud-based access to support decision-making and ensure regulatory compliance.

Uncover Valuable Insights: Browse Blogs, Guides, and Video Tutorials

- Connecting corporate and site control systems in remote silver mining operations with DeltaV, SQL server, and business systems

- Linux MES to OPC Operations Data Integration in Aluminum Smelting Operation

- Secure remote site integration with OPC, Excel, and Simulation System integration

- Linux MES to OPC Operations Data Integration in Aluminum Smelting Operation

- LGH History Data Facilitates Predictive Maintenance

Video Tutorial

Deployment Guide

TOP Server Secure Deployment Guide

This guide provides best practices that existing and new users should consider if their business needs require deploying TOP Server with maximum security.

Why Work With Software Toolbox? Our Clients Tell Their Story:

“I am very happy as always with the support received for this case. In particular, I want to point out the commitment by the consultant to get this issue resolved. It was not an easy case to solve because a number of configuration aspects were specific to our infrastructure. However, in the end through the persistence of the consultant the case was solved and we all learnt a great deal about this particular aspect of the system. The support from Software Toolbox is always excellent but on this occasion, it was at another level. I deal with a number of software vendors and Software Toolbox is by far the vendor I prefer to deal with the most. Keep it up!"

- A global mining group, British - Australian

“A simulation tool like Witness is generally hosted on another computer and needs to access Microsoft DCOM variables through different kinds of clients. But DCOM and its required settings are quite complex and not really fault-tolerant. To get things working, we used the OPC DataHub to avoid DCOM setting problems. The OPC DataHub establishes a tunnel between the OPC client and the server, allowing OPC data to pass through without any specific DCOM settings."

- Van Oudenhove, Ecole des Mines d'Albi-Carmaux (EMAC) , France

“Our application engineer found the help files very comprehensive to show how to do what you need to do, and the support from Software Toolbox to help validate that we were doing everything efficiently allowed us to implement this solution quickly.”

- Ismail Gattoo, Industry Software Solutions & Support (IS3), United States

Why Software Toolbox? Data-Focused, Solution-Oriented

Our world-class support ensures that we address your mining, metal, and mineral operations challenges with precision and care.

Software Toolbox offers top tier support and services designed to maximize the value mining, minerals & metals companies derive from our solutions. Whether optimizing mineral extraction, improving smelting processes, enhancing mine-to-mill integration, enabling environmental stewardship, or enabling predictive maintenance, our expert team provides personalized assistance to ensure smooth implementation and quick troubleshooting. With a customer-first approach, 97% of users rate our support as “awesome or excellent.” We empower our clients to overcome operational challenges, improve efficiency, and optimize performance across applications like asset performance management, environmental monitoring, energy optimization, and regulatory compliance in the mining, metals, and minerals sectors.

Software Toolbox provides the mining, metals, and minerals industry with secure, reliable, and scalable data solutions. By seamlessly integrating data across field operations, processing plants, and enterprise systems, we help you overcome communication barriers, drive operational efficiency, and make smarter, more data-driven decisions in critical areas such as mineral extraction, processing optimization, sustainability, and supply chain management.

STAY CONNECTED

1-888-665-3678 (US + Canada)

+1-704-849-2773 (Global)

+1-704-849-6388 (Fax)

support.softwaretoolbox.com

WORKING WITH US

WHO WE ARE

RECENT POSTS

Usage subject to our website terms and conditions.