Industrial Connectivity

HMI/SCADA Add-Ins

Digital Transformation

Application Development

Enabling Life Sciences Innovation & Delivering Results |

|

Secure, Compliant, and Reliable Data Solutions

Software Toolbox provides secure data communication solutions used in applications that optimize operations, performance, and compliance in the life sciences and pharmaceutical industries. Our intelligent tools enable seamless integration across research, production, and distribution environments, including applications like laboratory management, packaging, labeling, traceability, testing, cold chain monitoring, facility monitoring, operations, inventory control, and medical devices manufacturing. We believe that product quality and patient safety are of outmost importance to your business, and our software and the way we work with you must support, not hinder these objectives.

By facilitating real-time data aggregation, connectivity, and sharing of data between systems, our software enables secure and smooth data exchange and integration across diverse devices and systems. The pharmaceutical and life sciences industries have a wide range of unique devices, especially in inspection, end-of-line packaging, inline testing, and lab testing and we have flexible software to help integrate them. We know you are constantly striving to enhance operational efficiency, streamline resources management, empower decision makers with real-time insights and actionable intelligence, and must always adhere to industry regulations like 21 CFR Part 11, Annex 11, USP, PICS, ICH, and GxP.

Ultimately, our solutions, services, and proven support help simplify data integration, reduce downtime, and enable operational efficiency while strengthening the resilience and security of critical pharmaceutical operations.

Transforming Operations Through Agile and Scalable Software

-

Real-Time Monitoring and Control of Manufacturing & Laboratory Environment

-

Data Historization & Long-Term Data Storage

-

Regulatory Compliance & Validation

-

Predictive Maintenance & Operational Continuity

-

Supply Chain & Inventory Management Optimization

-

Batching & Production Process Control

Real-Time Monitoring and Control of Manufacturing & Laboratory Environment

Software Toolbox’s solutions enable seamless connectivity and real-time data aggregation from sensors, packaging & labeling equipment, and manufacturing, laboratory, and inspection systems. This enables system visibility, helping customers optimize performance, manage resources, and reduce downtime in critical production and testing environments. Our solutions streamline data collection from the plant floor to the cloud, eliminating silos by unifying data from on-premises systems, edge devices, and cloud platforms for better decision-making and compliance.

Data Historization & Long-Term Data Storage

Storing, retrieving, and analyzing massive amounts of process and historical data is critical for regulatory compliance, quality control, and operational insights. Software Toolbox’s solutions help facilitate data collection and advanced historian integration, ensuring secure, scalable, and high-performance storage of real-time and historical data. By bridging field devices, controllers, HMI/SCADA systems, MES platforms, cloud services, and enterprise databases, our solutions empower manufacturers with long-term trend analysis, predictive modeling, and compliance reporting, all while maintaining data integrity and accessibility for audits and regulatory reviews.

Regulatory Compliance & Validation

Pharmaceutical and Life Sciences companies must meet strict 21 CFR Part 11, FDA, and GxP requirements for data integrity, electronic records, and process validation. Software Toolbox’s solutions help ensure compliance by delivering secure, auditable data collection, enabling full traceability and automated reporting to streamline regulatory audits and validation activities. Our technology helps organizations maintain data integrity, minimize risk, and streamline compliance efforts—ensuring every process and system meets industry standards.

Predictive Maintenance & Operational Continuity

By integrating real-time data from equipment, production lines, and manufacturing systems, Software Toolbox’s solutions provide the data required to identify potential failures early and enable proactive maintenance. This minimizes downtime, ensures the continuous operation of critical systems and ultimately supports uninterrupted production cycles—crucial for the pharmaceutical manufacturing process where operational continuity is key to meeting demand and regulatory standards.

Supply Chain & Inventory Management Optimization

Software Toolbox’s solutions optimize supply chain operations and inventory management by providing real-time visibility and data integration across the entire pharmaceutical supply chain. From raw materials to finished products, our solutions enable product tracking, monitoring and control of inventory levels, packaging processes, and distribution. By aggregating data from warehouse management systems, tracking sensors, and production lines, we help life sciences and pharmaceutical companies improve operational efficiency, reduce waste, and ensure traceability throughout the process.

Batching & Production Process Control

Software Toolbox’s solutions enable the optimization of batching and production process control through real-time data collection and storage, helping to improve the batching process and ensure consistent product quality and compliance with Good Manufacturing Practices (GMP). By integrating data from sensors and controllers used in recipe management and manufacturing execution systems (MES), we enable accurate batch tracking, minimize human error, and improve production efficiency. This empowers pharmaceutical companies to maintain seamless production workflows, reduce downtime, and help in batch consistency and traceability.

Overcoming the Challenges in Life Science & Pharmaceutical Operations

-

Reliable Connectivity Across Disparate Systems

-

Real-Time Monitoring & Visualization

-

Data Integration & Security

-

Streamlining Application Deployment

Challenges

Integrating diverse systems like laboratory equipment, inspection systems, labeling & packaging, facilities monitoring and control, and manufacturing control systems is difficult due to differing protocols and siloed data. This causes inefficiencies, downtime, and limited decision-making, impacting performance and costs.

Solution

Software Toolbox solutions enable seamless data collection from various devices, connecting systems with TOP Server and OmniServer. These tools improve interoperability, streamline workflows, reduce downtime, and ensure compliance across diverse platforms.

Challenges

Pharmaceutical operations require real-time data for compliance and quality. Without centralized visualization and reporting, stakeholders struggle to interpret trends, track performance, and make timely corrective decisions.

Solution

Software Toolbox provides solutions like Dream Report and Flow to visualize and interpret data. This helps improve monitoring, decision-making, compliance, and product quality by simplifying data analysis.

Challenges

Unifying data across on-premises systems, edge devices, business systems, and cloud platforms is complex and hinders real-time insights and decision-making. Cybersecurity risks and compliance issues add complexity in life sciences and pharmaceutical operations.

Solution

Software Toolbox’s solutions enable secure, seamless integration across OT, IT, ET, and cloud platforms. Cogent DataHub supports secure real-time data exchange in complex network architectures while OPC Router provides templated visual workflow data integration and transformations, ensuring compliance and operational efficiency in pharmaceutical and life sciences operations.

Challenges

Creating solutions for manufacturing, labs, and compliance processes is resource intensive. Life sciences companies need tools that streamline deployment while ensuring efficiency, security, and compliance with regulations like GxP and 21 CFR Part 11.

Solution

Software Toolbox provides tools that simplify and de-risk custom application development, ensuring scalability, security, and seamless integration. OPC Data Client and OPC Wizard toolkits enable standards based OPC interfaces in those applications, removing the need to be an OPC expert. Symbol Factory offers pre-built visual elements for process visualization.

Maximize Operational Performance through Data Integration

Here are examples of our configurable off-the-shelf software solutions for life sciences and pharmaceutical industries. Our consultants help identify the ideal mix that integrates seamlessly into your environment, within your budget.

TOP SERVER

TOP Server is a secure platform for integrating critical data in pharmaceutical and life sciences facilities. It supports applications like production monitoring & control, data historians, environmental monitoring & control, and system management, ensuring compliance and operational efficiency.

OMNISERVER

OmniServer integrates legacy equipment and advanced environmental monitoring systems in pharmaceutical and life sciences operations. It simplifies communication with non-standard devices, improving operational visibility, energy monitoring, and predictive maintenance.

DREAM REPORT

Dream Report improves compliance and performance monitoring in pharmaceutical operations by transforming raw data into actionable insights. It tracks production metrics, energy usage, and regulatory compliance with customizable templates with all the tools required to build a 21 CFR Part 11-compliant reporting solution.

OPC ROUTER

OPC Router is a visual workflow and data integration platform that integrates data from cloud, business systems, and scientific systems. It has high availability through application-level redundancy. It optimizes production workflows, balancing, and predictive maintenance for pharmaceutical operations.

SYMBOL FACTORY

Symbol Factory improves user interfaces in pharmaceutical operations for HMI/SCADA systems. It visualizes real-time data, enhances system status assessment, and reduces downtime, improving efficiency in regulated environments like cleanroom monitoring.

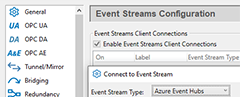

COGENT DATAHUB

Cogent DataHub enables integration of real-time and historical data across pharmaceutical operations, supporting asset management, capacity planning, and disaster recovery. It ensures compliance with cybersecurity standards while enabling large-scale data exchange and system interoperability

Unlock More Insights: Browse our articles, case studies, and tutorials

- Waste Reduction in Automation Using OmniServer »

- 4 Ways to Address Security Challenges with Cogent DataHub Tunneling »

- OPC Connectivity & Security Concerns in IT/OT Convergence »

Case Study

- Data aggregation and secure OPC data transmission Yokogawa DCS and GE PLC control systems at Teva Pharmaceuticals »

- Biomedical Engineering project support

Deployment Guide

TOP Server Secure Deployment Guide »

This guide provides best practices that existing and new users should consider if their business needs require deploying TOP Server with maximum security.

Why Work With Software Toolbox? Our Clients Tell Their Story:

"Once again, Software Toolbox was very helpful. As the support team coached me through the

process, I was able to voice my own ideas and concerns. By Software Toolbox creating a

dialogue and only jumping in when I absolutely needed the help, I was able to learn a lot.

Now, I’m more confident about helping team members, and I’m excited by all of the possible

ways we can use Software Toolbox products in the future. Two thumbs up!"

- Multinational Healthcare Company , Switzerland

“I received all the information I needed to help make an informed decision on how to proceed with our project.”

- One of the world's largest suppliers of contact lenses, lens care products, prescription pharmaceuticals, intraocular lenses and other eye surgery products., Global

Why Software Toolbox? Expert support and seamless integration for Smart Cities, BMS, and FMS.

Our world-class support ensures that we help Pharmaceutical and Life Sciences companies overcome operational challenges with precision and care.

Software Toolbox delivers exceptional world-class support and services to help pharmaceutical companies maximize their investment in our solutions. With a customer-first approach, 97% of our users rate our service as “awesome or excellent.” Our expert team provides personalized support to ensure smooth implementation, fast troubleshooting, and ongoing system optimization. We offer comprehensive assistance in addressing challenges such as enhancing real-time data collection in manufacturing that help ensure regulatory compliance (e.g., GxP, 21 CFR Part 11), and improve performance across critical applications like manufacturing execution systems (MES), clinical trial management, batching, and quality control. Whether you're streamlining production workflows or optimizing research data management, Software Toolbox is committed to providing the tools and expertise needed to drive operational success and innovation in life sciences and pharmaceutical industries.

STAY CONNECTED

1-888-665-3678 (US + Canada)

+1-704-849-2773 (Global)

+1-704-849-6388 (Fax)

support.softwaretoolbox.com

WORKING WITH US

WHO WE ARE

RECENT POSTS

Usage subject to our website terms and conditions.